The B-TEK Learning Center

Resources to help you scale your business with B-TEK.

Expired

Proper truck scale calibration is essential for ensuring accurate, reliable weighments, particularly in industries where precision is critical. Calibration should only be handled by a certified scale technician who uses a test truck equipped with certified test weights to fine-tune the scale. Here's a breakdown of the truck scale calibration process:

Step 1: Unloading Test Weights

The technician arrives on-site with a certified test cart loaded with 25,000 lbs of test weights. These weights are essential for ensuring calibration accuracy. Each weight is certified to meet the National Institute of Standards and Technology (NIST) guidelines, providing a trustworthy baseline for calibration.

The technician arrives on-site with a certified test cart loaded with 25,000 lbs of test weights. These weights are essential for ensuring calibration accuracy. Each weight is certified to meet the National Institute of Standards and Technology (NIST) guidelines, providing a trustworthy baseline for calibration.

Step 2: Testing Each Scale Section ("As Found")

The technician runs the test cart across each section of the scale to record the initial accuracy of the equipment, known as the "as found" condition. This provides a snapshot of how the scale is performing before any adjustments are made.

The technician runs the test cart across each section of the scale to record the initial accuracy of the equipment, known as the "as found" condition. This provides a snapshot of how the scale is performing before any adjustments are made.

Step 3: Making Adjustments

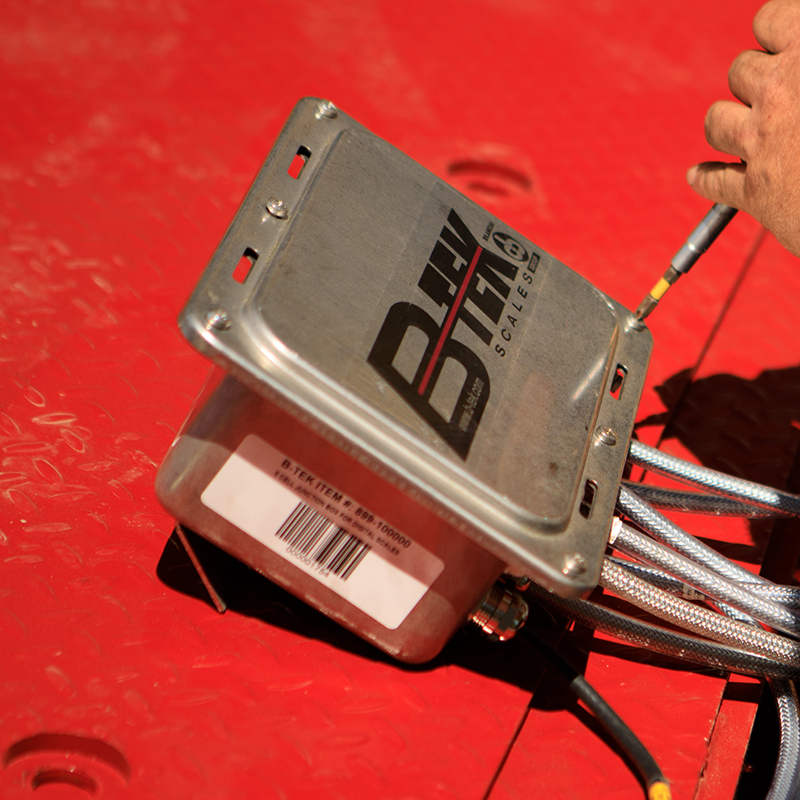

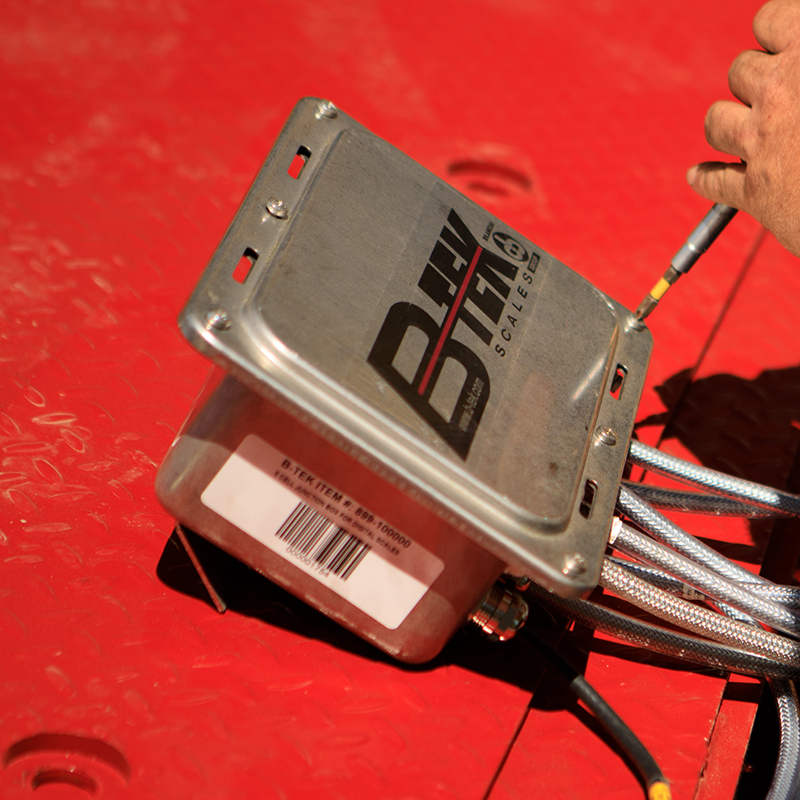

Once the technician has the "as found" data, adjustments are made using the junction box, which allows fine-tuning of the scale. This step ensures that all sections of the truck scale are aligned and reading weights accurately.

Once the technician has the "as found" data, adjustments are made using the junction box, which allows fine-tuning of the scale. This step ensures that all sections of the truck scale are aligned and reading weights accurately.

Step 4: Calibration

With the junction box adjustments complete, the technician performs the actual calibration, which involves ensuring that the scale’s indicator matches the known test weights exactly.

With the junction box adjustments complete, the technician performs the actual calibration, which involves ensuring that the scale’s indicator matches the known test weights exactly.

Step 5: Retesting After Adjustment

After calibration, the technician reloads the test cart and weights and reruns the same process to verify the accuracy of the scale's measurements. This final check ensures that no errors were introduced during adjustment.

After calibration, the technician reloads the test cart and weights and reruns the same process to verify the accuracy of the scale's measurements. This final check ensures that no errors were introduced during adjustment.

Step 6: Full-Truck Test and Report

The process concludes with a full-truck test, where the technician ensures that the entire system is functioning accurately. They complete the "as left" section of the calibration report, certifying the scale for continued use.

The process concludes with a full-truck test, where the technician ensures that the entire system is functioning accurately. They complete the "as left" section of the calibration report, certifying the scale for continued use.

Why Regular Calibration Matters

Regular truck scale calibration is crucial for industries that depend on precision. Inaccurate readings can lead to financial loss, compliance issues, and operational inefficiencies. B-TEK’s NTEP-approved truck scales and indicators are engineered to simplify this process, allowing for straightforward calibration, quick adjustments, and reliable results every time.

Regular truck scale calibration is crucial for industries that depend on precision. Inaccurate readings can lead to financial loss, compliance issues, and operational inefficiencies. B-TEK’s NTEP-approved truck scales and indicators are engineered to simplify this process, allowing for straightforward calibration, quick adjustments, and reliable results every time.